Welcome to the Rudloe and environs website.

Here you will find news, articles and photos of an area that straddles the Cotswold Area of Outstanding Natural Beauty in north-west Wiltshire.

Contributions in the form of articles or photos are welcome. Even those with completely contrary views to mine!

Thanks to the website builder 1&1 and Rob Brown for the original idea.

Rudloescene now, in January 2014, has a sister, academic rather than anarchic, website about Box history here: http://www.boxpeopleandplaces.co.uk/

It contains thoroughly professional, well-researched articles about Box and its people.

Contact rudloescene through the 'Contact' page.

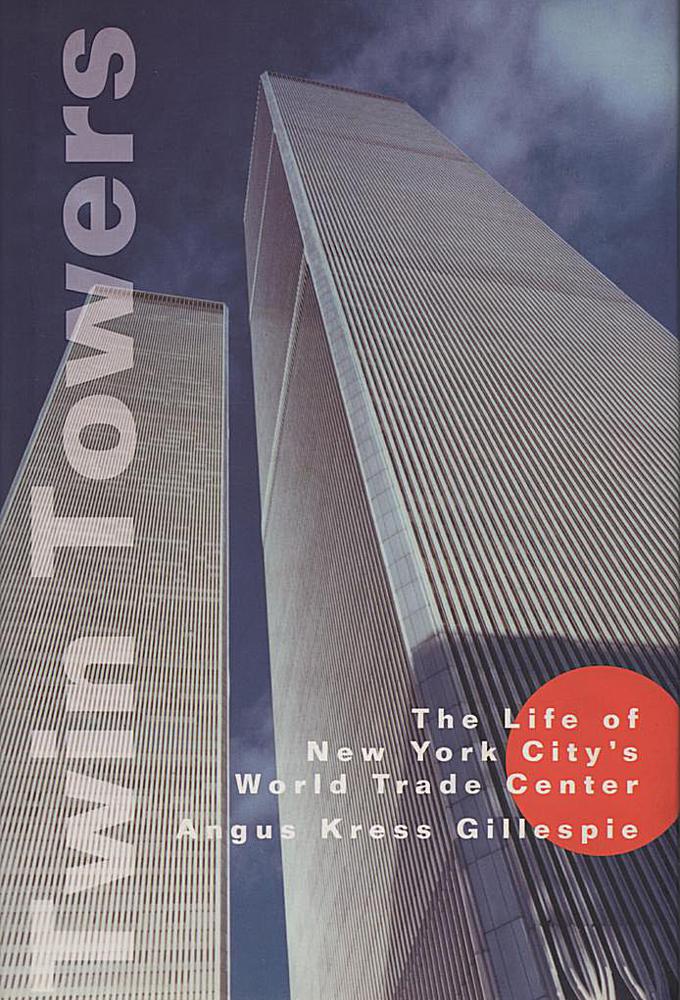

This week (writing this on 8th September 2021) brings the 20th anniversary of 9/11. The title picture shows the dust jacket of Twin Towers, a 1999 book (reprinted in 2001 and dedicated to those who lost their lives on September 11th 2001) which covers the political background (34 pages that cover the years 1961 to 1966), overcoming obstacles (and there were many), the construction, and so on through to day-to-day life. The book illustrates that the towers were not just two columns of steel and concrete but an astonishingly complex structure which took 12+ years to complete (from conception in 1961 to dedication in 1973). The project manager said that every such project can be broken down into six phases: 1. enthusiasm, 2. disilluisionment, 3. panic, 4. search for the guilty, 5. punishment of the innocent and 6. praise and honour for the nonparticipants. He wasn't to know that there would be a seventh phase - destruction. The following paragraphs highlight some of the interesting (hopefully) aspects of the Twin Towers revealed in the book.

From the late 90s through the mid-noughties, a circle of friends from Corsham and Rudloe decamped to New York to work. At various times (some for the whole time and some remain there), Derek, Wayne, Martin, Richard, Pete, Jason, Matthew, Craig, James and Paul (x2) were installed in Lower Manhattan. Their apartment(s) were enclosed within the 'exclusion zone' following 9/11. Pictures of these times (including a photograph taken from the roof of one of their apartments of the towers burning) follow the Twin Towers information.

The Towers.

Discussing the foundations, the book says ..."It must be remembered that Manhattan is an island situated at the confluence of a major river and the ocean. To reach bedrock, engineers would have to dig down sixty-five feet. They knew that half the site would be where the Hudson River used to be; excavate only three feet and they would hit water. All conventional methods had substantial drawbacks. Finally, the 'slurry trench' method was adopted. It was a big gamble because no one knew if it would really work. There were no American firms available for the work so it had to be done by an Italian company. How did it work? As the dirt and rock were removed, it was constantly replaced by a 'slurry', a mixture of water and bentonite, a type of fluffy, expansive grey clay (with a texture of pea soup) that comes from Wyoming. It had a swelling tendency and would plug any holes along the sides as the excavators dug deeper. It was strong enough to hold back the groundwater and maintain the sides of the trench without any bracing. They were able to continue this process right down to bedrock."

"Apart from the foundations, there were two other technological innovations: the elevators and the structure itself. It was the development of elevators in the first place that led to the construction of skyscrapers. Elevators enabled architects to design taller and taller buildings. But the higher you go, the more people in the building; the more people in the building, the more elevators you need. The more elevators, the less floor space to rent."

The solution adopted was described as follows: "Divide each tower into three parts or zones. Express elevators from the lobby will be the biggest in the world, each carrying 55 passengers. Then three local zones will sit on top of each other. Each zone will have its own lobby. People will transfer from express to local in the second and third zones by crossing the lobby. All the local elevators will sit on top of one another within a single shaft thus solving the problem of usable space."

The diagram illustrates the three zones divided by the 44th floor and 78th floor lobbies. (There are 254 elevators in total)

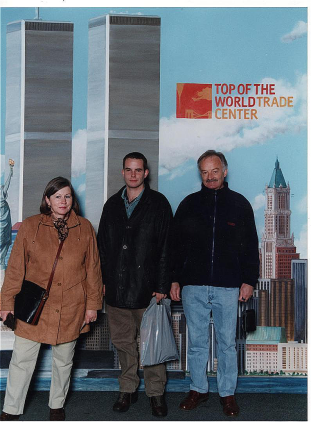

See later photo of three Rudloeites in the 78th floor lobby following a nightime visit to the observation deck.

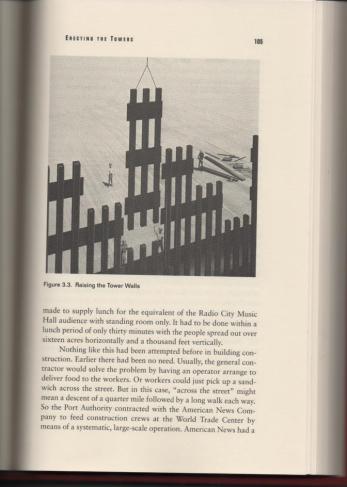

The third technological innovation was the structure itself. "The system was entirely new and different from other, conventional high-rise buildings. Ever since the nineteenth century, the skyscraper had been built with a network of interior supporting columns. This was the skeleton that supported the structure. The exterior walls were just 'curtain walls' that admitted light and kept out the rain. But in the World Trade Centre buildings, the exterior walls carry he vertical loads as well as resisting all lateral winds. This was accomplished by using high-strength steels never before available. The only interior columns were in the core that housed the elevators. The trick on getting the outer wall to carry veryical loads came in closely spacing the vertical columns which were three feet nine inches apart and serve as frames for the floor to ceiling windows which are only twenty-two inches wide. These give a feeling of complete security even for most people with a fear of heights."

The photograph shows the exterior wall columns being lifted into place. This is remeniscent of the fallen towers where these structures could be seen rising from the debris.

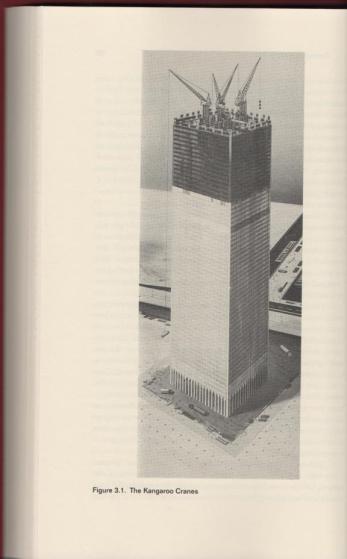

But first, there was the problem of delivering steel* to the site. "The steel wasn't really 'delivered' until it reached the floor where it was needed. Usually, derricks are used, mounted to the building itself but these have to be lifted to a higher position, one floor at a time which usually takes about 36 hours, not to mention the problem of providing the derrick with a strong base from which to work. In addition, power was normally supplied from the ground using cables running down through floors already built."

"What was needed was a crane that could carry its own power aloft and was equipped with hydraulics to raise itself. Such a crane was found in Australia, manufactured by Favelle Mort Ltd of New South Wales. Because of its origin, it was quickly nicknamed the 'kangaroo crane'. There were four of these cranes, one at each corner of the elevator core. When the steel for three floors was lifted and placed, the cranes could lift themselves up the next three floors. Their diesel motors drove a series of hydraulic lifts installed at the base of each crane. Moving in twelve-foot 'heaves', the cranes lifted themselves upward to the next position in about two hours."

(The book also contains an interesting section on getting the cranes back down again)

* see later section on the Karl Kock Erecting Company

The Mohawks

"Most people will have heard stories that many of the ironworkers on skyscrapers are Native Americans. Such stories are plausible but are they true accounts or just contemporary folklore? In the case of the World Trade Centre, the stories are not only engrossing but happen to be true. Some of the earliest newspaper accounts of the construction of the Twin Towers confirm that Mohawks were among these skilled ironworkers. In October 1968, reporter John Metcalfe wrote: 'A force of 45 of these sure-footed, cool-headed specialists is now employed. Among them are twelve Mohawk Indians, members of that tribe which jet-propelled itself from the stone age into the skyscraper era by learning to handle hot rivets and cold steel. This gang spends the week in Brooklyn and every weekend commutes all the way up to their homes in Canada.'"

"In a 1949 essay, Joseph Mitchell described them as follows 'They have high cheekbones and jut noses, their eyes are sad, shrewd and dark brown, their hair is straight and coal black, their skin is smooth and coppery; they walk in a beautiful, chin-lifted and haughty fashion.'"

"According to Mitchell, the Indians became involved with 'high steel' in 1886 when they were hired for bridge construction across the Saint Lawrence River near their home, the Kahnawake reservation. In exchange for the right to use reservation land in building the bridge, the Dominion Bridge Company promised the Indians employment on the bridge work. The company had intended to employ them as ordinary workers unloading materials but the Indians were unhappy with that arrangement. They kept coming out onto the bridge at every opportunity. In a letter to Mitchell, a company official explained: 'As the work progressed, it became apparent that the Indians were very odd in that they did not have any fear of heights. If not watched, they would climb up into the spans and walk around up there as cool and collected as the toughest of our riveters most of whom were old sailing ship men picked for their experience in working aloft. The Indians were as agile as goats. They would walk a narrow beam with nothing below them but the river. They were inquisitive about the riveting and were continually bothering our foremen by requesting that they be allowed to take a crack at it. This happens to be the most dangerous work in all construction, and the highest paid. Men who want to do it are rare and men who can do it ever rarer and in good construction years there are sometimes not enough of them to go around. We decided it would be mutually advantageous to see what these Indiand could do, so we picked out some and gave them a little training, and it turned out that putting riveting tools in their hands was like putting ham with eggs.'"

"We are left to wonder what in the Mohawks' background would give them this extraordinary ability. In any event, they were soon working on every high, steel bridge or skyscraper in Canada. Later, they started going all over North America, including, of course, New York and New Jersey."

Asbestos

"It had been standard practice for years, in steel buildings, to use spray-on fireproofing containing asbestos. This was regarded as necessary because steel, in a fire, will bend and warp. However, the use of asbestos had come under scrutiny as it had recently been proven that asbestos caused cancer. The Environmental Protection Agency issued a set of standards covering the spraying of asbestos-containing materials. The EPA was especially concerned because in the spraying process as much as 50 percent of the asbestos escapes into the air. By this time, construction had already reached the thirty-fourth floor. Two difficult decisions were then made, first to stop using fireproofing with asbestos and second to change all of the spray at a cost of $300,000. In retrospect, the decision to change to a new material (not specified which - PT) was the right one. To remove asbestos from just one floor of the centre would have cost more than a million dollars."

The Environment

"In addition to the mounting political and economic arguments against the World Trade Centre, a rash of environmental arguments began to emerge (in 1971 - PT). New Jersey newspapers reported that the World Trade Centre was dumping 170,000 gallons of raw sewage daily into the Hudson River. The report was true, but not the whole truth as, at that time, all Manhattan sewage from 72nd Street down to the Battery was being discharged into either the Hudson or the East River." (A sewage treatment facility in Brooklyn had not yet come on line).

"There was no way for tenants to turn off lights as there were no light switches. The lights burned all day, even in areas of the building where plenty of daylight came through the windows. Those who insisted on having a light switch were billed $142."

The Karl Koch Erecting Company

"For erecting all of the 192,000 tons of steel required, a competent contractor had to be recruited. From the point of view of the Port Authority (the owners of the site and sponsors of the scheme - PT) it was desirable to have a single, reputable contractor for the whole job. After long negotiations, Karl Koch Erecting Company of the Bronx was awarded the $20 million contract in January 1967. But there was a downside to this 'lump sum' deal, in that financial success depended on accurate estimation of costs, always tricky in construction work. Nonetheless, Karl Koch signed on the dotted line."

"As the work continued, costs spiralled and Karl Koch began to have financial difficulties. One morning Koch came into Monti's (Construction Manager) office and threw his keys and wallet onto Monti's desk. Koch said, 'You've got everything else. Now you can have my Cadillac, my twelve (!) kids, my wife and my house because I have nothing else left and besides, I'm going to kill myself so it really doesn't matter'. Monti replied, 'Karl, why don't you let me take you to lunch? Then you can kill yourself this afternoon.'

Over lunch they were able to work out a framework of an agreement whereby the Port Authority would bankroll the firm so that the job could be finished."

Another Mohawk?

"The newly completed towers became the premiere attraction for daredevils from all over the world. The first of these individuals was Phillipe Petit from Nemours, France. He, with the help of four others, ran a slender tightrope across the tops of the Twin Towers and walked across it early in the morning of 7th April 1974.

A contemporary account described how Petit was able to accomplish this feat. Three days earlier, he and four others disguised themselves as construction workers and took cables and other equipment to the uppermost floors of the North Tower. They were able to load their supplies onto a freight elevator, store them just nineteen steps below the roof and move about freely. Two assistants then took up position on the roof of the South Tower. On the night before the walk, Petit and friends stationed themselves on the roof of the North Tower. Using a five-foot crossbow, they shot an arrow with a strand of nylon fishing line attached across to the South Tower. They passed progressively heavier lines until the 131-foot cable was strung."

"Once the main cable was in place, the men attached guy lines from the cable to the roof to keep swaying to a minimum. At one end the cable was attached to a steel stanchion; at the other, a winch was used to regulate the tension. On the morning of the walk, Petit hesitated (no kidding - PT) as there was a stiff breeze but he started off anyway. A crowd gathered below. Petit made eight trips across the tightrope aided by a thirty-eight-foot-long balancing pole (What? That's enormous. - PT). He stopped several times to sit or lie down. He hung by his feet. One witness recalled him doing a handstand."

The Corsham/Rudloe connection

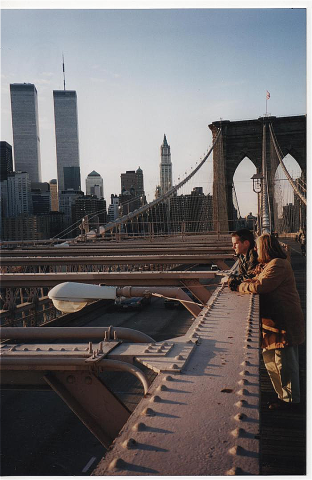

In a period from the late-90s to the mid-noughties, a group of friends from Corsham and Rudloe lived and worked in New York. Their accommodation was in Manhattan's Lower East Side in what was once part of the huge De Lancey Estate. There was a significant Jewish community in the area but originally it was an area called Kleindeutschland (Little Germany) as a large number of German immigrants had settled there.

In the 20th-century, it became part of the New York art and music scene. Amongst many others, Lou Reed, John Cale and Sterling Morrison of The Velvet Underground lived and recorded there. At the end of the block was Katz's Deli (when we visited, we received the injunction "Don't go there, it's disgusting" but we did, and it was) which became famous for the 'orgasm scene' in the film When Harry Met Sally. The apartment interior was used in the filming of Along Came Polly, a 2004 film starring Ben Stiller and Jennifer Aniston.

The apartment was a mile-and-a-half from the Twin Towers as the crow flies (the distance from Rudloe to Corsham!).

Top of the World Trade Centre

Later that day, as evening approached, we decided to take the trip to the top of the World Trade Centre and, unusually, we opted to have a picture taken by the official photographer in the lobby on the 78th floor.

By the time we reached the observation deck it was dark. New York, by night, whether from a plane or from the top of the World Trade Centre is an amazing sight. Of course, you get much more time to study (and reflect) from a tall building. Talking of reflection, HM wondered how you would get out in the event of a fire.